Advantages

- Raw materials sourced from renowned European steel companies.

- Key processes are equipped with the world's first-class precision equipment Saacke, Reishauer, Gleason-hurth, Klink.

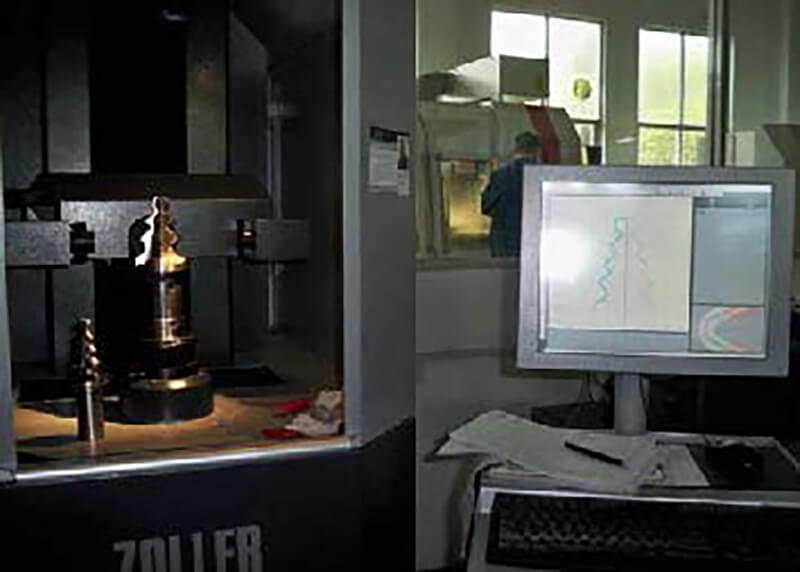

- Cutting tool is measured by the Klingelnberg gear tool measuring center.

- Optimize the heat treatment based on Saacke's, hardness is controlled within 1 HRC.

- Coatings are provided by Oerlikon Balzers.

About Us

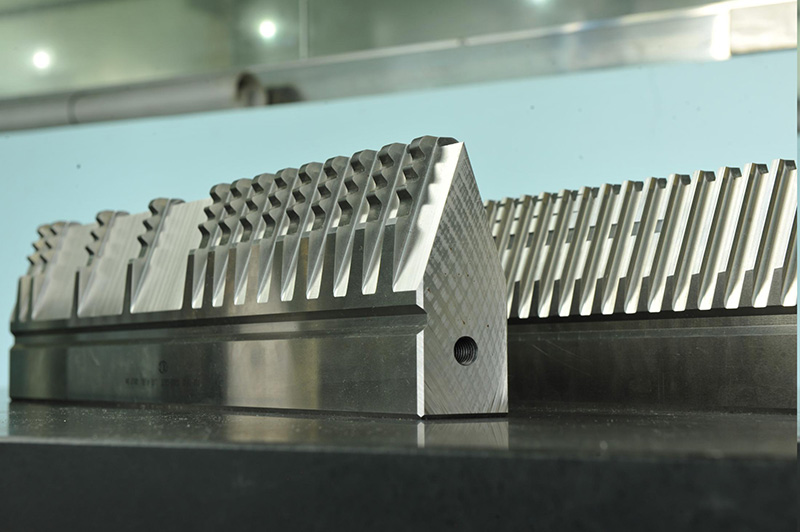

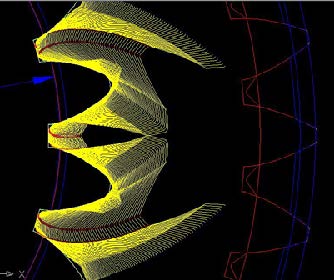

Htool was founded in 1968, have about 280 varieties and six categories of cutting tools, our main products are: Hobbing Cutters, Shaving& Shaping Cutters, Broaching Tools, Gleason Spiral Bevel Gear Cutters, Special Shaped CNC Cutting Tools, Special Cutters for Steam Turbines, Threading Rolling Dies, Drills, Milling Cutters and Reamers etc.

Factory largely equipped with international first-class precision CNC equipment and precision testing instrument series, adopt international advanced heat treatment process and Balzers coating technology.

We could afford high precision, high efficiency, high reliability, and customized metal cutting tools for the automotive, aerospace, energy, engineering machinery, metallurgy, mining, petroleum, heavy machinery, machine tools, ships, locomotives, military industry and other industries.

We warmly welcome friends to visit to us at any time!

Application of Us

Specialized metal cutting tool for automobile, construction machinery, metallurgy, mining, petroleum, heavy machinery, machine tool, locomotive and vehicle, energy and other industries.

- Automative

- Aircrat

- Agriculture

- HeavyPlant

- Mining & Oil exploration

- Pumps & compressor

- Marine application

- Military

- Windpower

Measuring

Cutting tool is measured by the Klingelnberg gear tool measuring center.

Raw materials

80% percent of our cutter materals are from the Bohler and the Erasteel in Europe.

We are the biggest partner of Bohlerin Asian.

We used different cutter materals for different cutting condition and using requirement.

Our solid carbide blank is from the top provider in Europe.

Machinery Equipment

More than 30 world first-class level manufactureing machines and 4 measuring instruments were introduced, such as German SAACKE Relief Grinding Machines, and Sharpening Machines , Swiss REISHAUER Relief Grinding Machine,and German SMS Relief Machines, German KLINGELNBERG Measuring Centers.

These Machines ensure that Our hobs keep at the interantional level.

Our advanced international CNC production lines, ensure identical manufacturing accuracy and using life of each product.Our high level and manufacturing equipment cluter can guarantee the delivery time of the big order.The shortest delivery time 15 workdays for hobs ,20 workdays for shaper cutters , 25 workdays for shaving cutters,35workdays for broaches

The company has all kinds of major production equipment and instruments more than 80,000 units (sets). All key processes are equipped with the world’s first-class precision equipment and series of precision testing instruments from Germany, Switzerland, the United States and Japan.

special equipment, including CNC hob sharpening machine, CNC grinding wheel line dresser, CNC shovel machine tools, CNC forming grinder, hob measuring instruments, vacuum quenching furnace equipment

Coating

SURFACE COATING Oerlikon Balzers coating center is inour company.All kinds of coatingare provided in thecenter.Uttermost increasingthe life of cutting toolsis the research objectof Balzers and usforever.

Heat Treatment

Our heat treatment technology is from Gemeny Saacke company. But we optimize the heat treatment based on Saacke’s

Controling and measuring the temperature of heat treatment by computer and heat sensor

The heating and insulation time of heat treatment is accurate to seconds.

The hardness are controlled within 1 HRC

We welcome you to visit our factory. Due to the distance from the office, please notify us in advance.